VIDEO TRANSCRIPTION

AIMS Education, UK

What is Logistics Management? Meaning, Importance, Basic Functions & Strategies - AIMS UK

Description generated by Skrybot

Explore the fascinating world of logistics - the art and science of acquiring, producing, and distributing materials and products in the right place and in the perfect quantities. This video dives deep into the realm of logistics management, a crucial part of supply chain management that strategically plans, implements, and controls the flow and storage of goods, services, and information.

Discover the 7 Rs of logistics that ensure the right product reaches the right customer at the right time and price. Learn about the various functions of logistics, including transportation, warehousing, third and fourth party logistics, reverse logistics, and the delicate balance between costs and customer service.

We delve into the goals of logistics which include rapidly responding to changes, minimizing service variances, reducing inventory costs, consolidating product movement, maintaining quality, and supporting the entire product lifecycle.

This video also unravels the secrets to effective logistics strategies, such as the importance of location, developing robust export/import strategies, selecting optimal warehouse locations, choosing the right transportation modes, selecting the best partners, and developing efficient information systems.

Learn how improved information can drastically reduce inventory costs by enhancing communication with suppliers, tracking inventory precisely, keeping inventory in transit, using postponement centers, tailoring shipments to match customer needs, and reducing time spent in customs.

Understand how reducing the number of supply chain partners can lower operating costs and inventory holding costs. We also discuss how pooling risks can help manage variability in demand for products.

Lastly, grasp the importance of the flow of goods and information in supply chains, requiring seamless internal process integration and collaboration. Dive into how customer information flows through the enterprise via orders, sales activity, and forecasts, leading to a value-added flow of goods when products and materials are procured.

Join us on this enlightening journey into the world of logistics and supply chain management.

Transcription generated by Skrybot

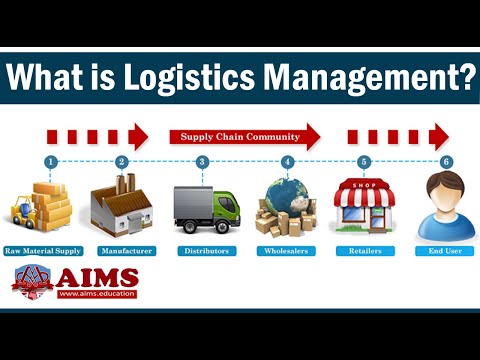

Logistics. It is defined as the art and science of obtaining, producing and distributing material and product in the proper place and in proper quantities. Logistics management. It is the part of supply chain management that plans, implements and controls the efficient, effective, forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption. in order to meet customers' requirements. Difference between supply chain and logistics Transforming a raw material into products and getting it to customers is supply chain, whereas movement of materials in the supply chain is logistics. The 7 Rs of logistics The most popular concept of logistics management is the concept of the 7 Rs.

It is concerned with getting the right product in the right quantity, in the right condition, at the right place, at the right time, to the right customer, and at the right price. Logistics functions Following the areas of logistics management contribute to an integrated approach to logistics within supply chain management. Transportation Many modes of transportation play a role in the movement of goods through supply chains, via air, rail, road, water or pipeline. Selecting the most efficient combination improves the value created for customers. Warehousing. When inventory is not on the move between locations, it may have to spend some time in a warehouse. Warehousing is the activities related to receiving, storing and shipping materials to and from production or distribution locations. Third and fourth party logistics.

Third-party logistics providers actually perform or manage one or more logistics services. Fourth-party providers are logistics specialists and play the role of general contractor by taking over the entire logistics function for an organization. Reverse logistics. It is a way to handle the return, reuse, recycling or disposal of products that make the reverse journey from the customer to the supplier. Logistics Value Proposition Managers must be able to balance logistics costs against the appropriate level of customer service. Logistics are usually managed as an integrated effort to achieve customer satisfaction at the lowest total cost. Therefore, service and cost minimization are two key elements in logistics value proposition. Logistics Goals and Strategies Logistics shares the goal of supply chain management to meet customer requirements. There are a number of logistics goals that most experts agree on.

Respond rapidly to changes in the market or customer orders. Minimize variances in logistics service. Minimize inventory to reduce costs. Consolidate product movement by grouping shipments. Maintain high quality and engage in continuous improvement. And support the entire product lifecycle and the reverse logistics supply chain. An effective logistics strategy depends on the following tactics. Coordinating functions, that is transportation management, integrating the supply chain, substituting information for inventory, reducing supply chain partners to an effective minimum number, and pooling risks. Substituting information for inventory. It is one of the tactics used to design effective logistics strategy. It requires taking a series of steps to construct the logistics network. Step 1. Locate in the right countries.

First identify all geographical locations and then analyze your forward and reverse chains to see if selecting different geographic locations could make the logistics function more efficient and effective. Step 2. Develop an effective export-import strategy. Determine the volume of freight and units that are imports and exports, and decide where to place inventory for strategic advantage. Step 3. Select warehouse locations. Determine the number of warehouses, calculate optimal distance from markets, and establish the most effective placement of warehouses around the world. Step 4. Select transportation modes and carriers. Determine the mix of transportation modes that will most efficiently connect suppliers, producers, warehouses, distributors and customers. Step 5. Select the right number of partners. Select the minimum number of firms, freight forwarders and third or fourth party logistics to manage forward and reverse logistics. Step 6.

Develops state-of-the-art information systems. It reduces inventory costs by accurately and rapidly tracking demand information and the location of goods. Substituting information for inventory. It is another tactic used to design effective logistics strategy. Physical inventory can be replaced by better information in the following ways. Improve communications. Talk with suppliers regularly. and discuss plans with them. Collaborate with suppliers. Use continuous improvement tools and share observations about trends. Track inventory precisely. It could be done by using GPS and barcode systems. Keep inventory in transit. It reduces inventory costs, for example cross-docking. Use postponement centres. Avoid filling warehouses with the wrong mix of finished goods. by setting up postponement centres, to delay product assembly until an actual order has been received. Mix shipments to match customer needs.

Match deliveries more precisely to customer needs, by mixing different SKUs on the same pallet and by mixing pallets from different suppliers. And don't wait in line at customs. Reduce the time spent in customs by clearing freight whilst still on the water or in the air. Reducing supply chain partners to an effective number. The more partners there are in the chain, the more difficult and expensive the chain is to manage. Consider a supply chain of three echelons between factory and customers, two factory warehouses, nine wholesale warehouses, and 350 retail stores. Reducing the number of partners reduces operating costs, cycle time, and inventory holding costs. When considering reducing the logistic partners, look for an entire echelon, such as all the wholesale warehouses or factory warehouses.

But if you eliminate all partners, you would be back to the vertical integration strategy. Pooling Risks When manufacturers and retailers experience high variability in demand for their products, they can pool together common inventory components associated with a broad family of products. to buffer the overall burden of having to deploy inventory for each discrete product. This is called pooling risks. This reduces storage costs and risks of stock outs by consolidating stock in centralized warehouses. Flow of goods and information. These flows exist in each supply chain. Enterprise must have internal process integration and collaboration between functions. as well as alignment and integration across the supply chain. Customer information flows through the enterprise via orders, sales activity and forecasts. Value-added flow of goods begins as products and materials are procured. .

S K R Y B O T

Skrybot. 2023, Video transcriptions from YouTube

By visiting or using our website, you agree that our website or the websites of our partners may use cookies to store information for the purpose of delivering better, faster, and more secure services, as well as for marketing purposes.